OptiSurf® LTM-Brochure

High-precision center thickness measurement of single lenses and doublets

Application Report

OptiSurf® LTM-Increases Production Efficiency at Pfeiffer Präzisionsoptik

TRIOPTICS‘ Solution for Non-contact Lens Center Thickness Measurement Significantly Reduces Reject Volume

Non-contact lens center thickness measurement increases throughput

OptiSurf® LTM

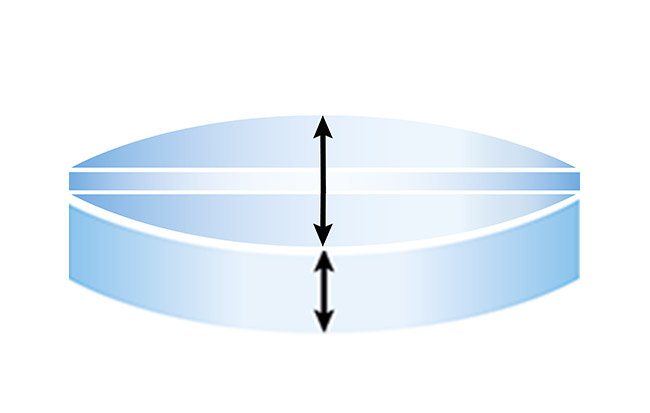

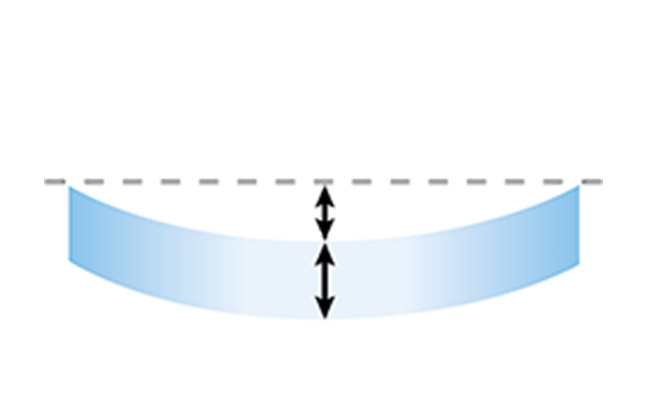

High precision center thickness and sag value measurement of single lenses and doublets

In optics production, the high quality of the single lens is the prerequisite for high-precision optical systems. With the OptiSurf® LTM (Lens Thickness Measurement), TRIOPTICS offers a precise center thickness measurement system for single lenses and doublets that seamlessly integrates into any production process. The high precision low-coherence interferometry is based on the established OptiSurf® technology and measures single lenses and doubles with a glass thickness of up to 150 mm with a precision of ±0,5 µm. The non-contact measurement system is gentle on sensitive surfaces and coatings. In addition to the center thickness, the sag value can also be determined.

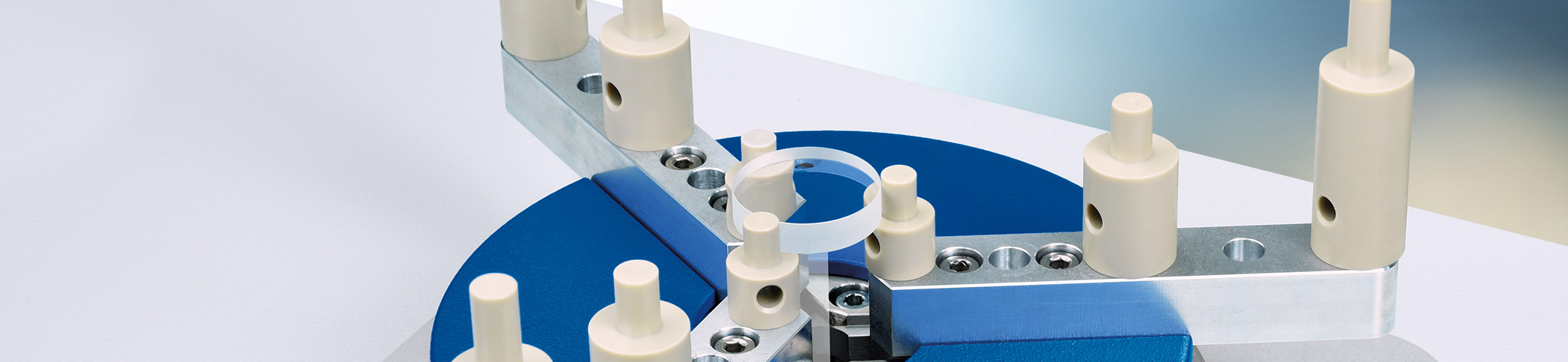

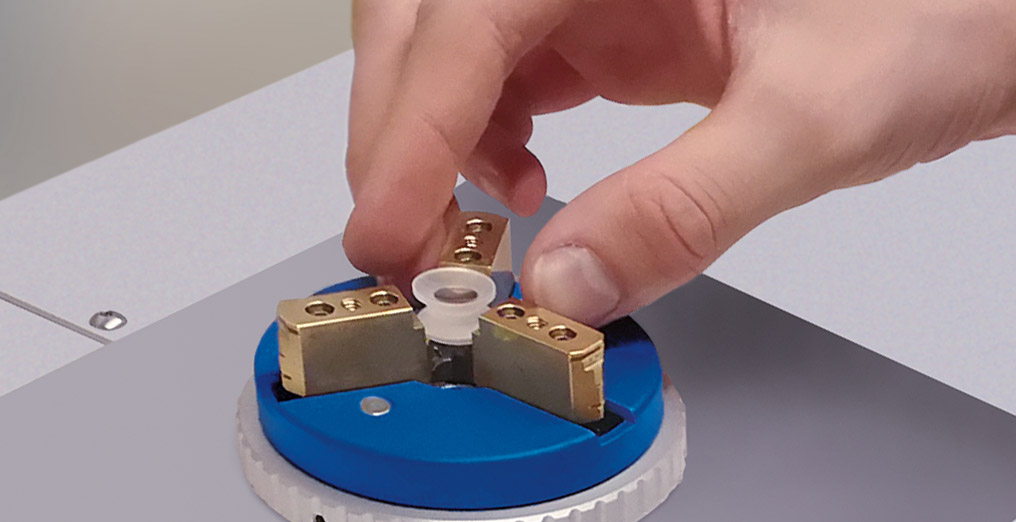

The optimization for use in production is particularly evident in its simple and stable handling. The OptiSurf® LTM is equipped with vibration damping and a self-centering mechanical clamping chuck. Two clamping chucks are available to choose from depending on the sample size (standard: 8 mm … 200 mm, micro: 1 mm … 30 mm). This eliminates any adjustment of the sample and the measuring process can be carried out safely, quickly and independently of the operator.

Simple operation is ensured by an integrated touch screen. For a straightforward data input a database can be called up via a network connection. The customer-specific connection of a barcode scanner is possible.

Applications

OptiSurf® LTM allow the measurement of:

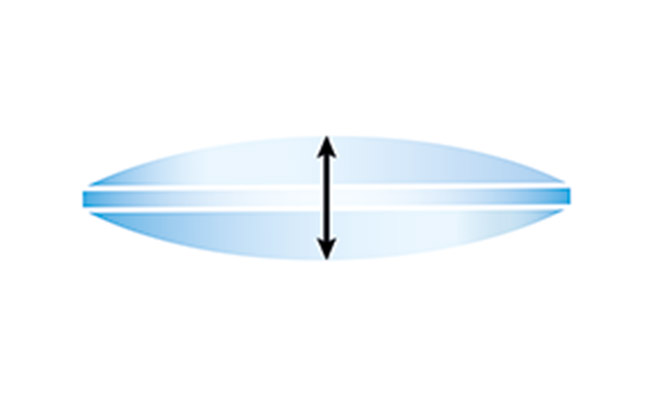

Center thickness of lenses

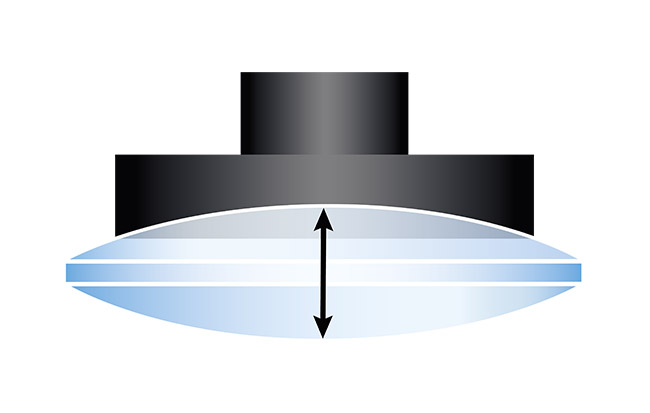

Center thickness of single lenses on an arbor

Overall thickness of doublets and individual thickness of the cemented lenses.

Sag value of concave lens surfaces

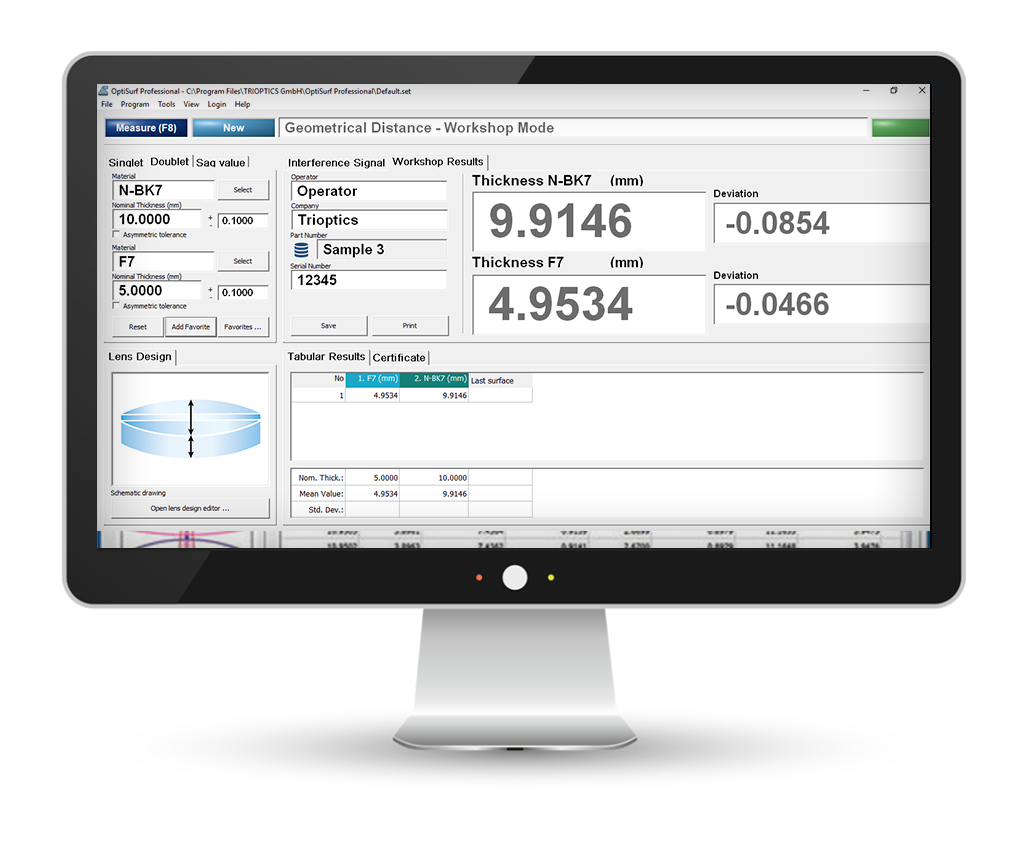

Software

OptiSurf® LTM Software

Simple handling – fast results

Just like the remaining design of OptiSurf® LTM, the software is also optimized for the quick measurement of single lenses as needed for smooth daily usage in optical workshops. The measurement settings are easy to configure and the results are presented in a way that is simple to understand. In addition, a pass/fail analysis of the measurement result is performed.

Upgrades & Accessories

Various sample holders are available to increase modularity.

Standard holder for samples with a diameter of 8 mm … 200 mm

Micro holder for test samples with a diameter of 1 mm … 30 mm

Knowledge Base

More knowledge for experts

This article inspired you? Are you looking for further knowledge transfer?

Then you might also be interested in the following topics …